Burner

- General information

- Variations

- Out technology – your advantage

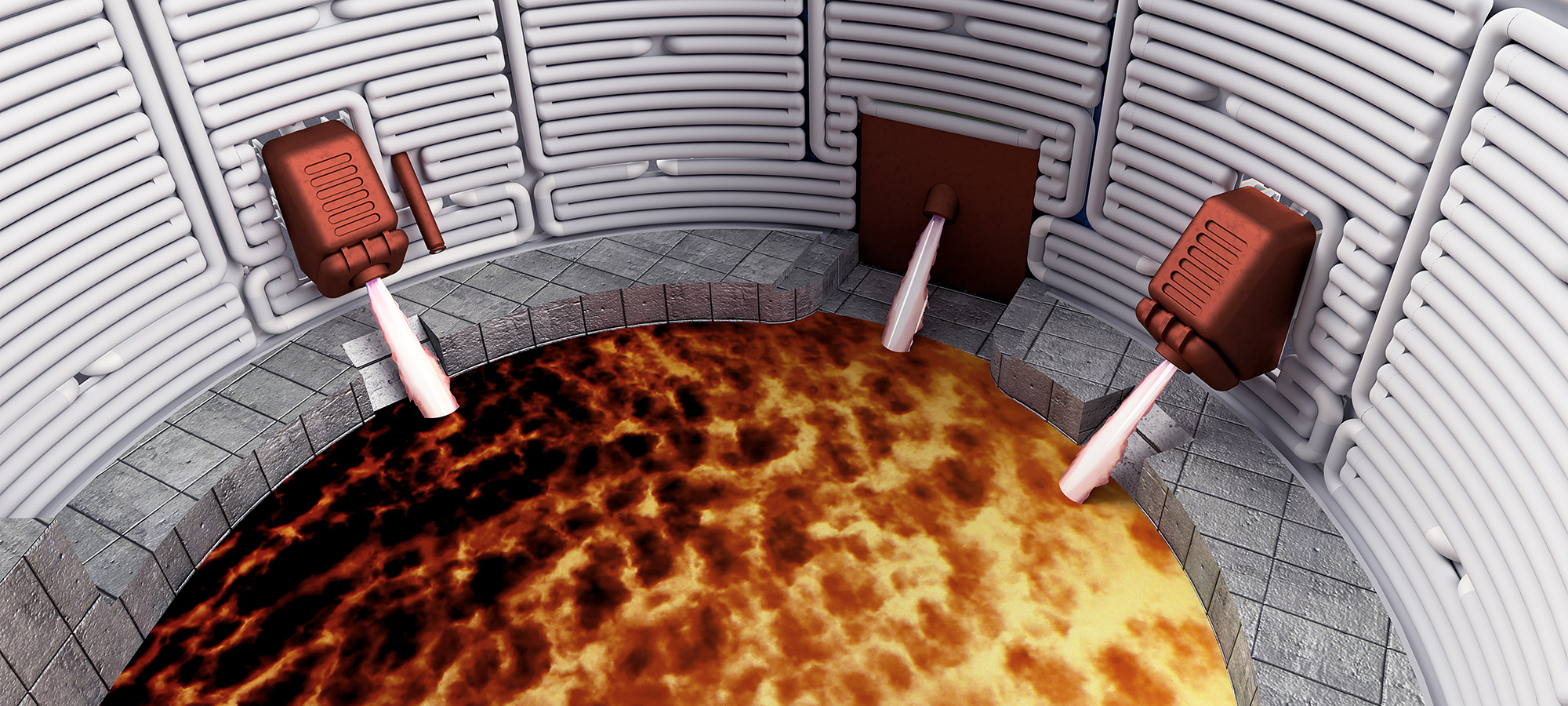

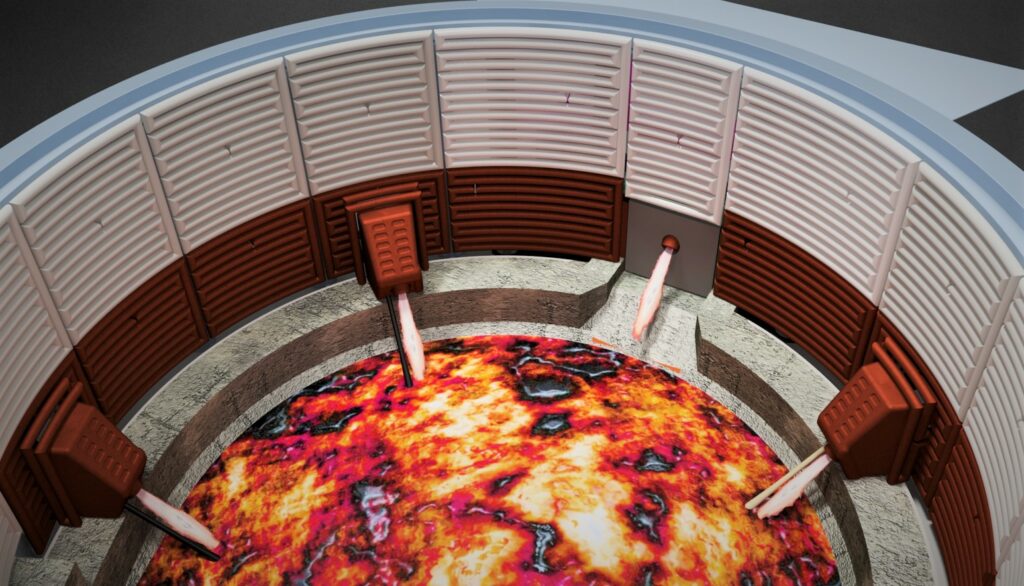

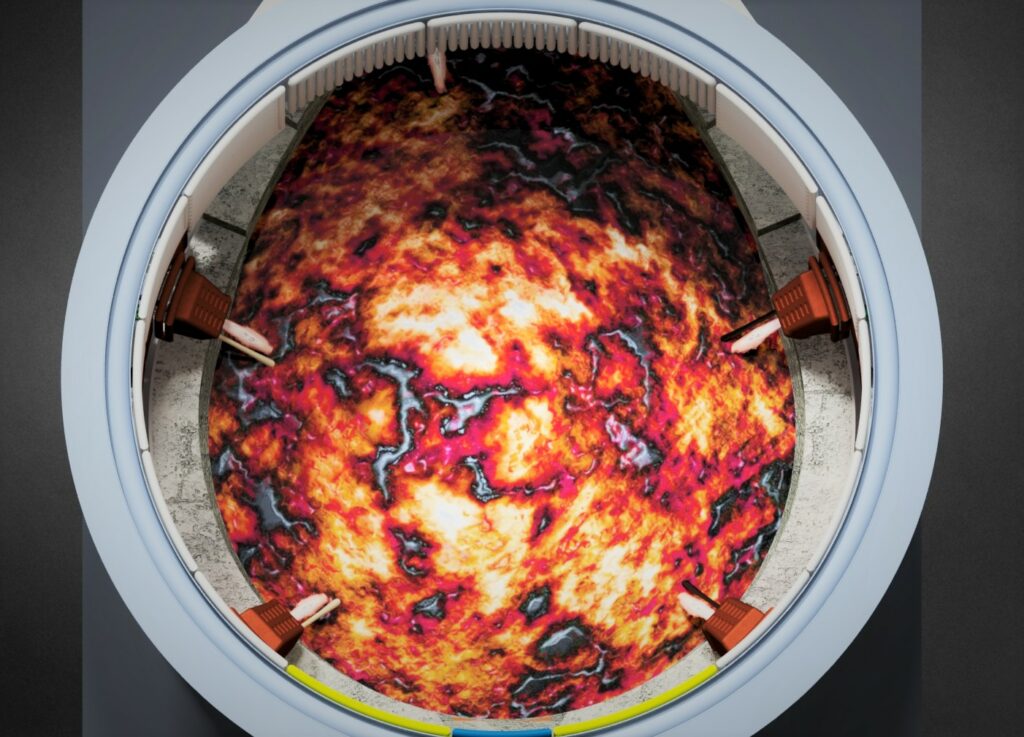

INTECO PTI’s concept has promoted the most aggressive introduction of oxygen and chemical energy into the Electric Arc Furnace (EAF) resulting in dramatic efficiency and utilization improvements. To employ this concept safely, INTECO PTI invented a unique water-cooled copper box (JetBOx™) which houses the burner and injector very low inside the EAF at a steep angle.

We offer different burner models and regardless of the burner type – they all have the same size to fit into all type of JetBOxes™.

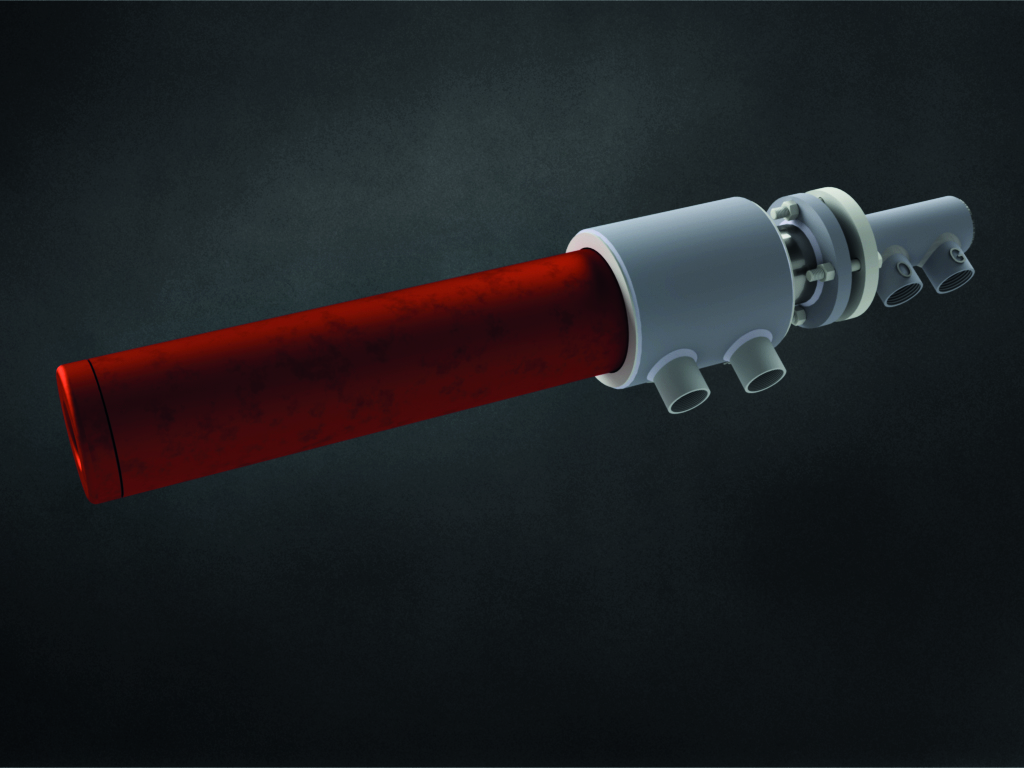

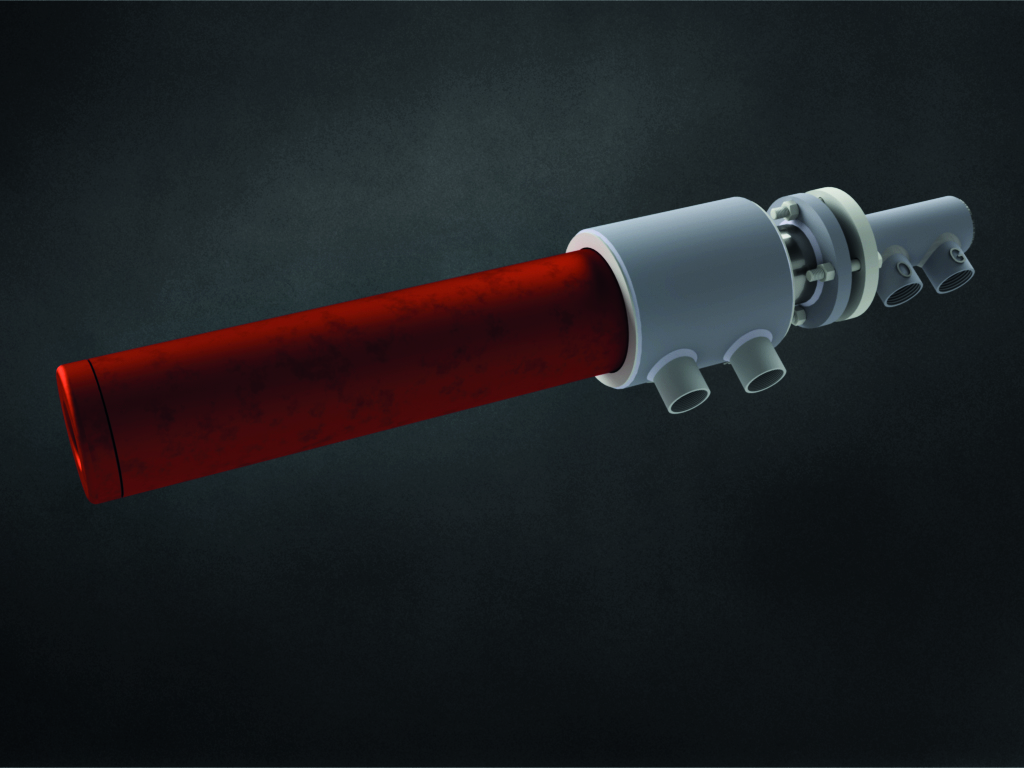

Combined burner and supersonic oxygen injector

The INTECO PTI JetBurner™ is both a standard oxy-fuel burner and a gas shrouded supersonic oxygen injector. The JetBurner™ produces a highly efficient flame and enables the oxygen to travel in a tight stream over a large distance.

Oxygen only supersonic injectors

While not as efficient as the shrouded oxygen injector, the oxygen-only, supersonic injectors provide highly velocity oxygen to processes that cannot use or do not have a combustible gas available.

Special application burners & Injectors

Some processes cannot use the standard PTI burner. For these processes, INECO PTI has developed special application burner/injectors. INTECO PTI can design a burner to fit the unique aspects of your process.

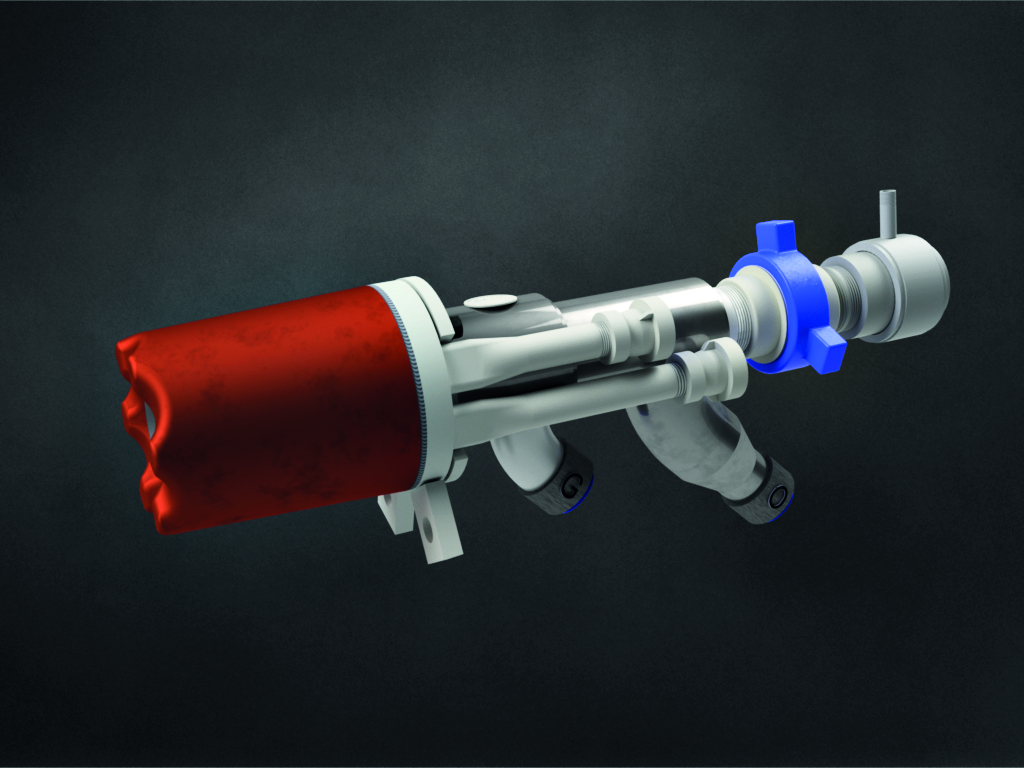

Material injectors

INTECO PTI has developed a supersonic oxygen injector that allows material injection during process. This injector clears an area inside the furnace so that material can be injected through the burner without blocking of the injection port or build-up within the furnace. Burner only applications are also available.

- Typical burner power up to 5MW

- Larger custom burner sizes are available

- Fuel types available: natural gas, LPG & diesel – others on request

- Supersonic oxygen injector (sizes start at 330 SCFM (530 Nm3/h) and are as large as 2,800 SCFM (4,500 Nm3/h)

- Fuel types available: natural gas, LPG & diesel – others on request

- Supersonic oxygen injector (sizes start at 330 SCFM (530 Nm3/h) and are as large as 2,800 SCFM (4,500 Nm3/h)

Burner

- General information

- Variations

- Out technology – your advantage

INTECO PTI’s concept has promoted the most aggressive introduction of oxygen and chemical energy into the Electric Arc Furnace (EAF) resulting in dramatic efficiency and utilization improvements. To employ this concept safely, INTECO PTI invented a unique water-cooled copper box (JetBOx™) which houses the burner and injector very low inside the EAF at a steep angle.

We offer different burner models and regardless of the burner type – they all have the same size to fit into all type of JetBOxes™.

Combined burner and supersonic oxygen injector

The INTECO PTI JetBurner™ is both a standard oxy-fuel burner and a gas shrouded supersonic oxygen injector. The JetBurner™ produces a highly efficient flame and enables the oxygen to travel in a tight stream over a large distance.

Oxygen only supersonic injectors

While not as efficient as the shrouded oxygen injector, the oxygen-only, supersonic injectors provide highly velocity oxygen to processes that cannot use or do not have a combustible gas available.

Special application burners & Injectors

Some processes cannot use the standard PTI burner. For these processes, INECO PTI has developed special application burner/injectors. INTECO PTI can design a burner to fit the unique aspects of your process.

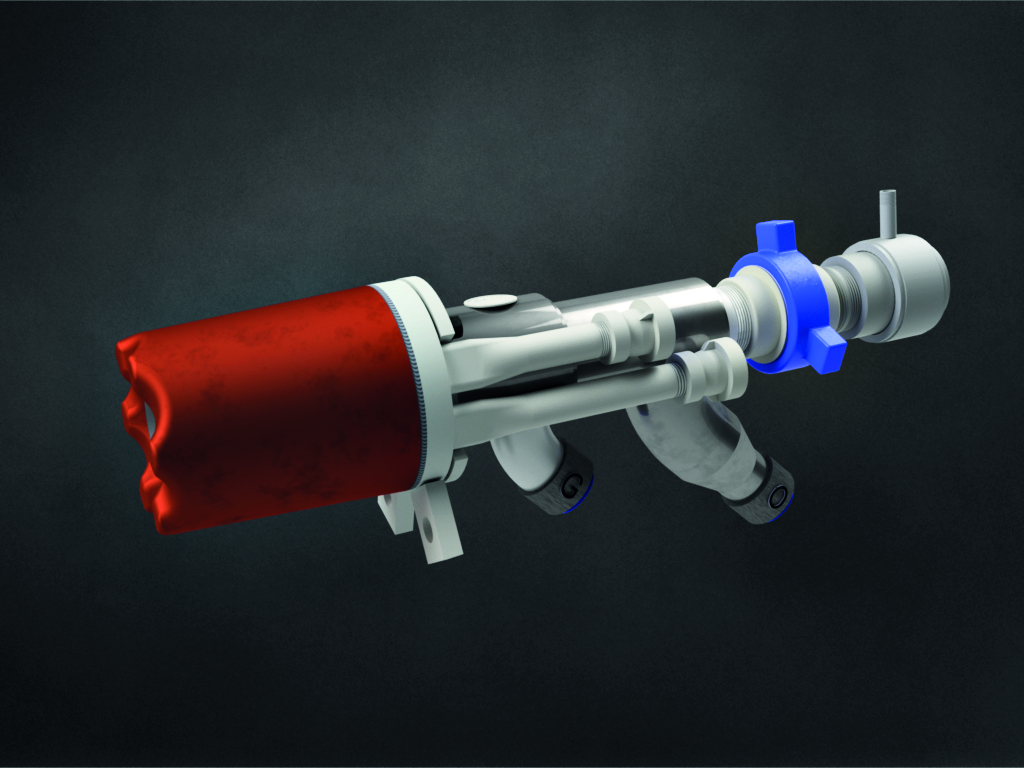

Material injectors

INTECO PTI has developed a supersonic oxygen injector that allows material injection during process. This injector clears an area inside the furnace so that material can be injected through the burner without blocking of the injection port or build-up within the furnace. Burner only applications are also available.

- Typical burner power up to 5MW

- Larger custom burner sizes are available

- Fuel types available: natural gas, LPG & diesel – others on request

- Supersonic oxygen injector (sizes start at 330 SCFM (530 Nm3/h) and are as large as 2,800 SCFM (4,500 Nm3/h)

- Fuel types available: natural gas, LPG & diesel – others on request

- Supersonic oxygen injector (sizes start at 330 SCFM (530 Nm3/h) and are as large as 2,800 SCFM (4,500 Nm3/h)