Preheaters & Dryers

- General information

- Variations

- Preheater system specifications

- Our technology – your advantage

You have modified your processes and purchased more efficient furnace equipment. You have added automation and have cut consumable expenses. You’ve saved all you can, right? Maybe not! Are you still using ancient preheater technology, running all day at one speed, doors wide open? Have you ever thought about how much that costs you?

INTECO PTI has a full line of dryers, preheaters, and combustion skids to fit your layout and your budget. We offer both oxy-fuel and air-fuel systems, so you don’t have to modify your plant floor or switch consumables. And, if you have not already chosen your consumables, let INTECO PTI design a system that will minimize your expenses.

INTECO PTI’s dryers, preheaters and combustion skids contain reliable starting mechanisms which wil start every time. The PLC controls allow variable firing rates and individual control of gas and oxygen profiles. This control results in less energy usage and increases savings.

Each INTECO PTI preheater comes with a visible alarm beacon and a self-diagnostic system, allowing your maintenance staff to quickly identify and correct any problems that may arise.

Further cost savings are available by utilizing your existing preheater and purchasing INTECO PTI’s control skid. This gives you all of the technology benefits of a full preheater system at a fraction of the cost. Let INTECO PTI tune your energy monster for good!

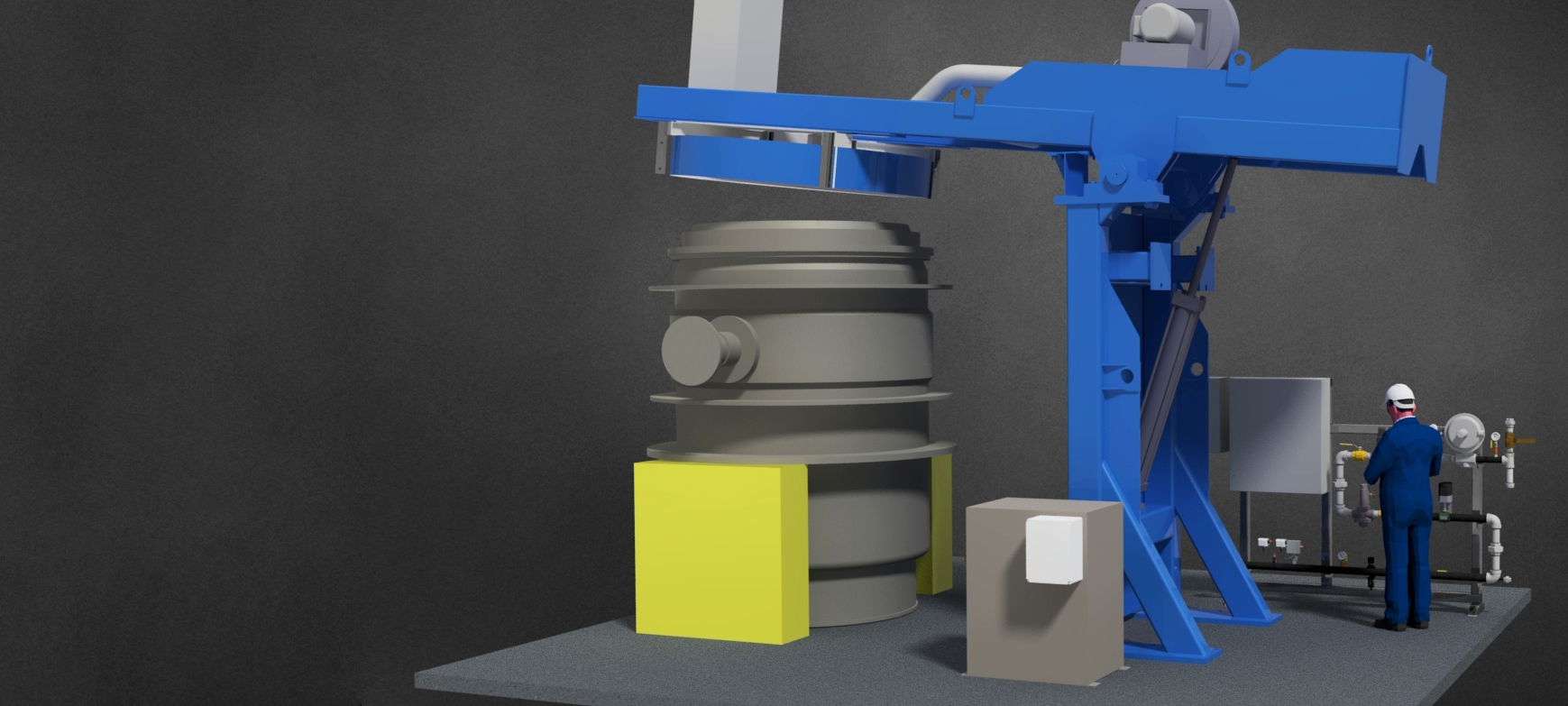

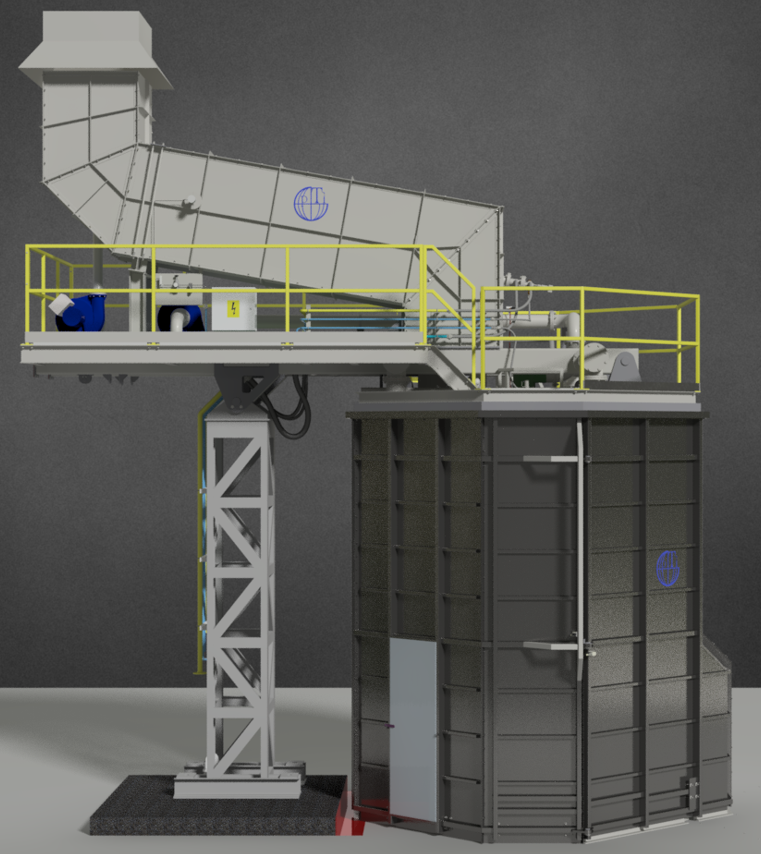

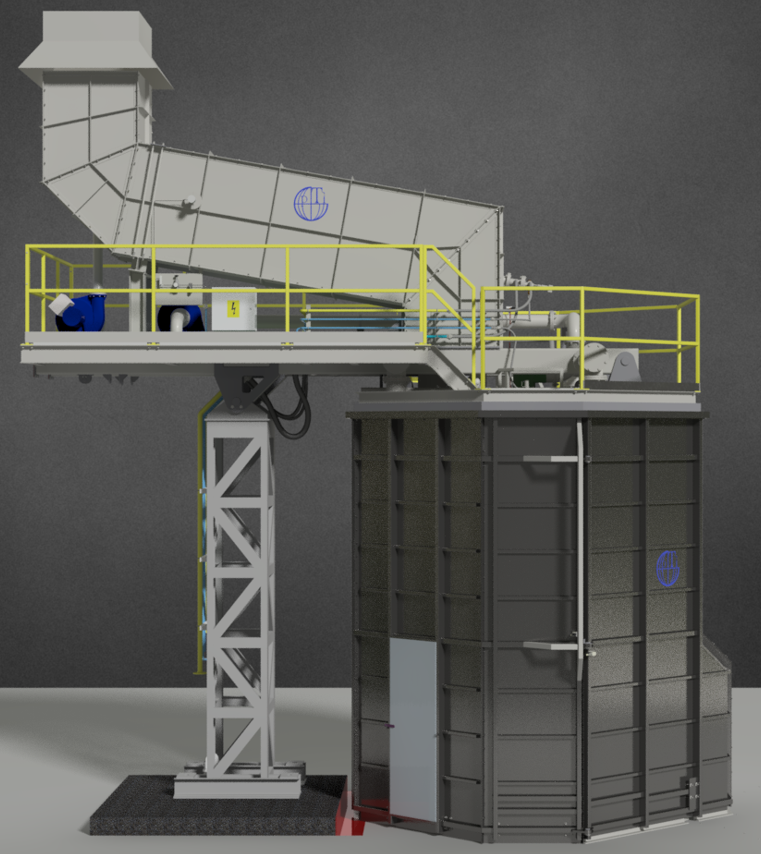

Vertical Ladle Preheaters

- All preheater systems are sized to fit the ladle or tundish

- Standard air/fuel or oxy/fuel burners are rated from 5 MMBTU to 15 MMBTU

- Bigger and smaller burners are available

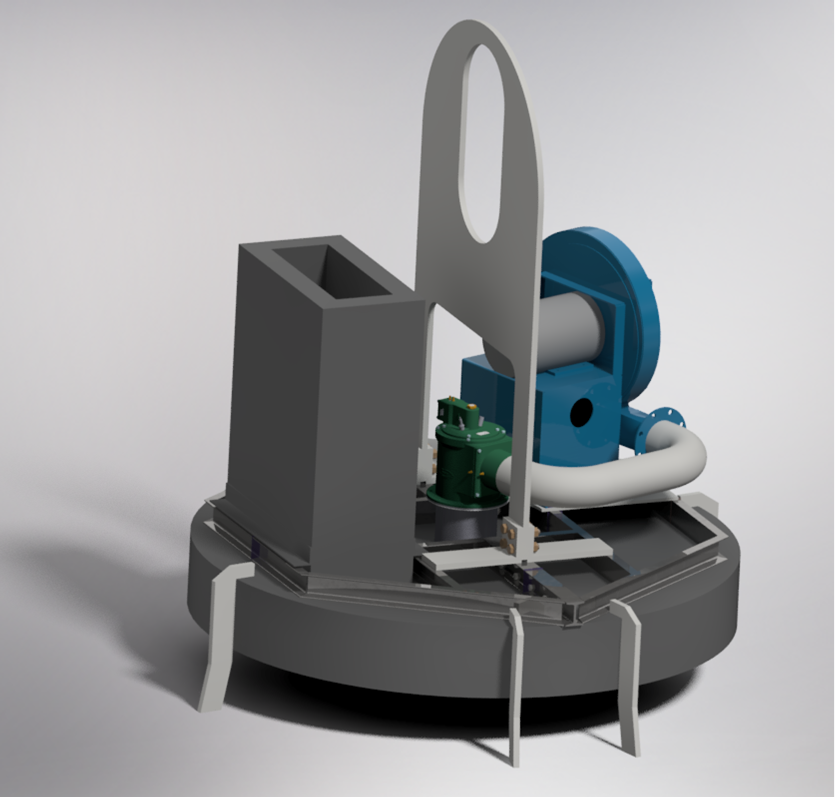

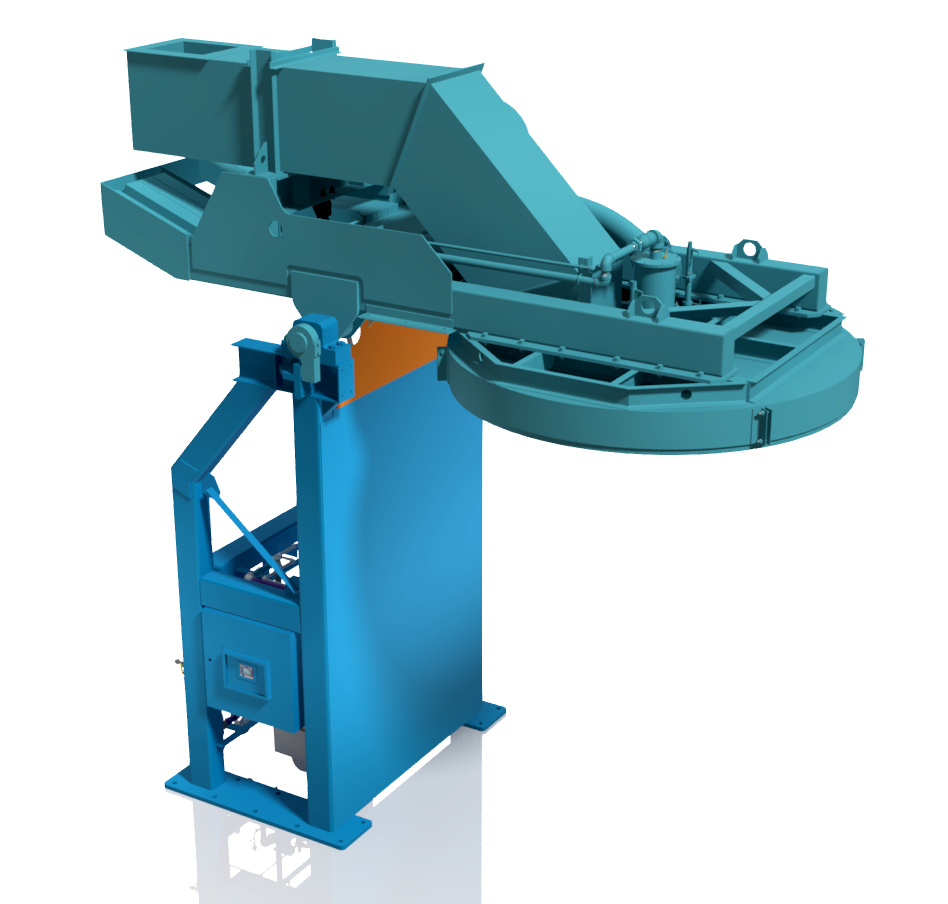

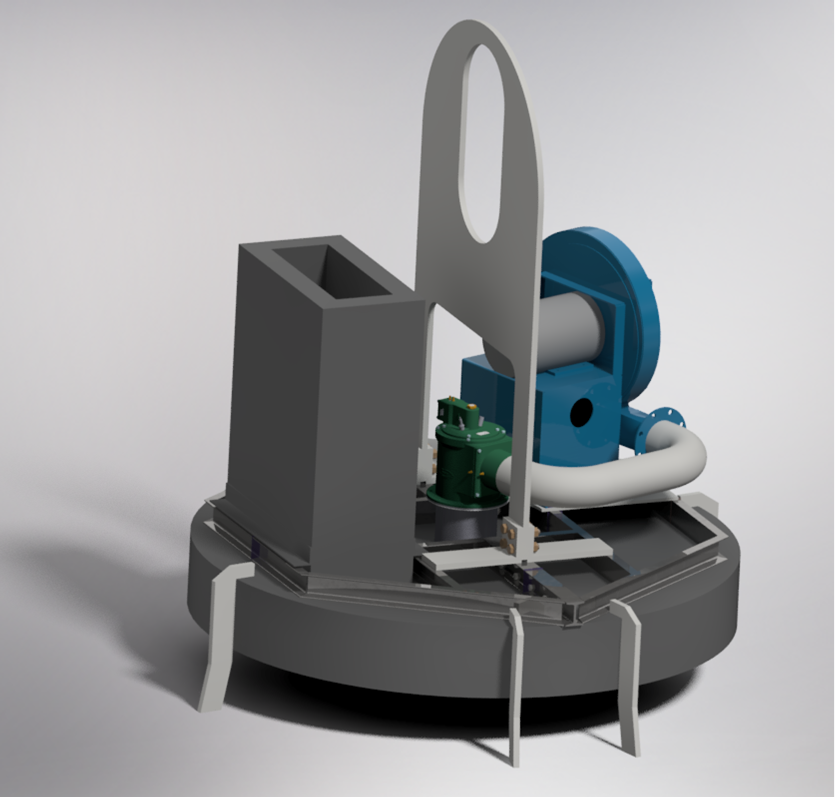

Portable Dryers and Preheaters

- Each portable preheater is sized to fit the ladle

- The lift mechanism is sized to fit the crane hook with a single center lift

- The blower is located on the lid, the control train is located remotely

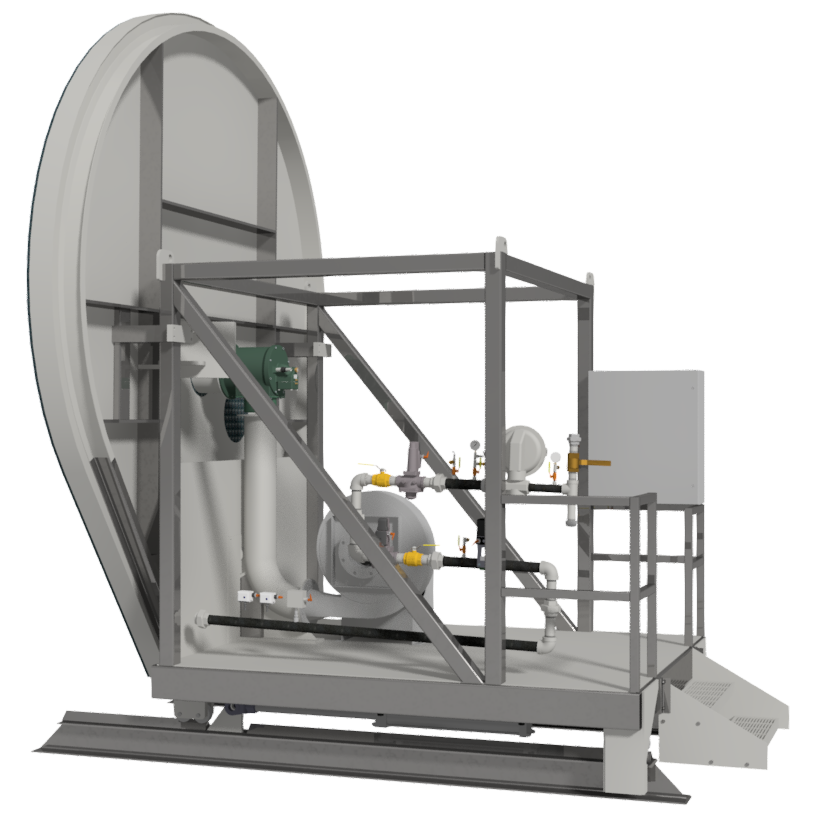

Enclosed Ladle Preheaters

- All air around ladle is captured and used for combustion An oxygen burner is used to combust all gases exiting the ladle exhaust

- All air around ladle is captured and used for combustion

- All air around ladle is captured and exhausted

Tundish Preheaters

- Tundish preheaters typically have one burner per pour nozzle

- Tundish preheaters can be lift-on or tilt-design

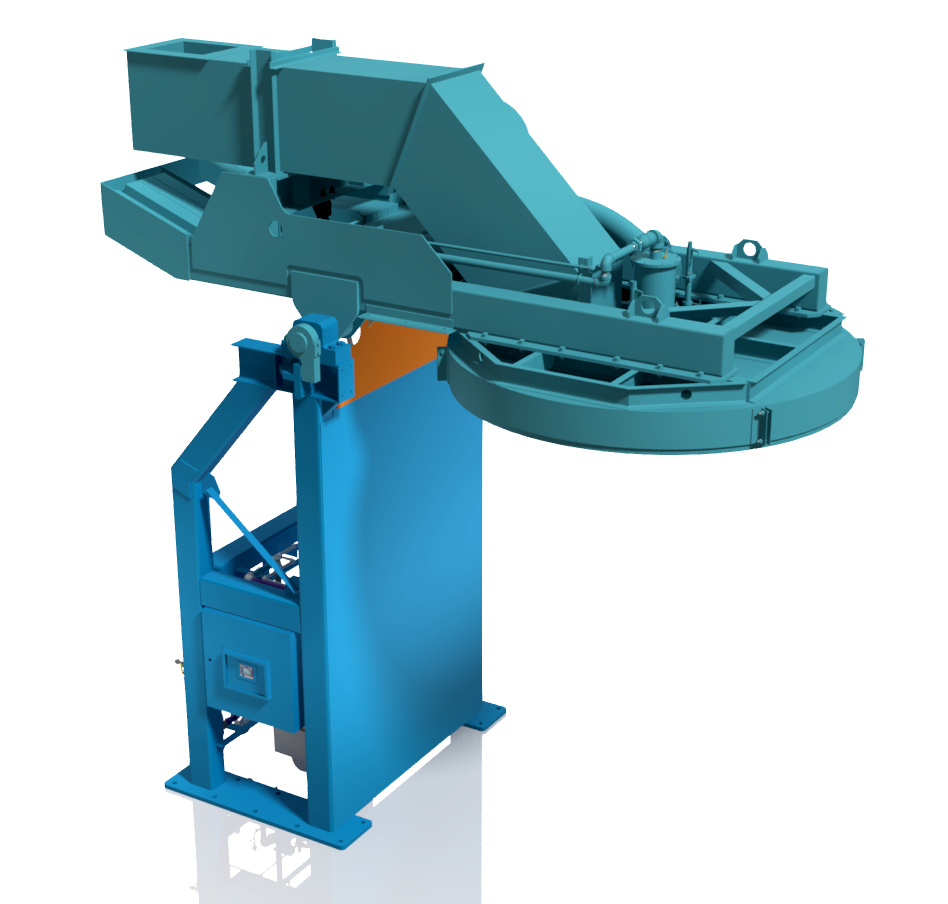

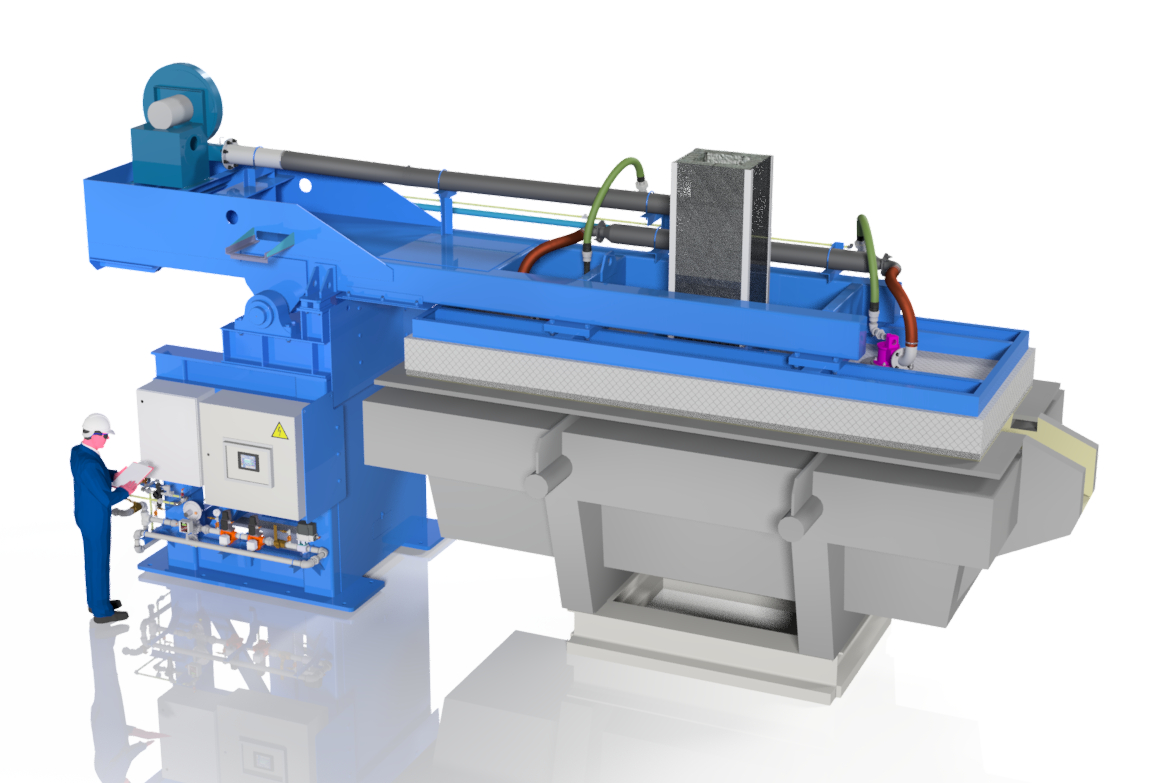

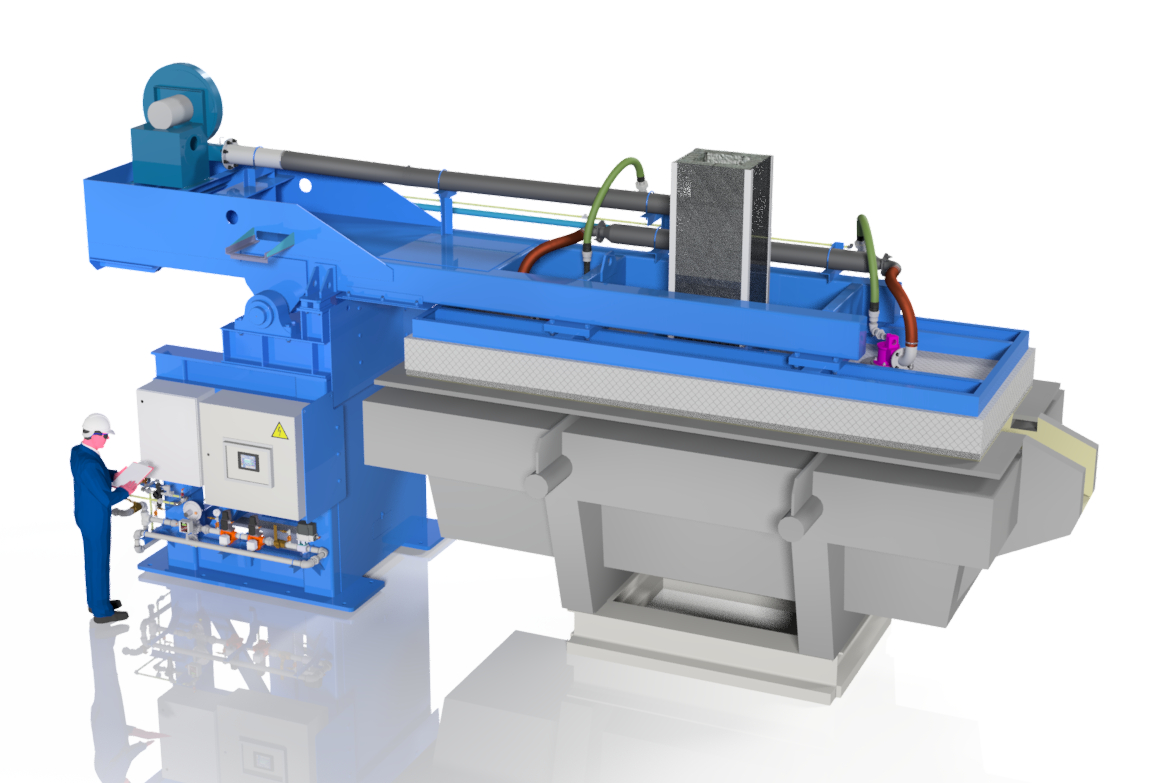

Horizontal Ladle Preheaters

- The cart is powered with pneumatics or hydraulics

- The ladle lid, control train and power system are all located on the cart

Refractory lids: The standard refractory lid consists of an angle iron and expanded metal frame with compressed refractory blocks. Four stainless steel plates are embedded vertically in the compressed refractory to act as a stop and keep the refractory from being crushed if the lid is closed against the ladle edge.

Burners: Standard Air/Fuel or Oxy/Fuel burners are rated from 0.1 MMBTU to 15 MMBTU. The burners are direct spark ignited; they do not require pilot burners. The burner is supplied with a UV-flame scanner, spark plug, and ignition transformer.

Air/gas train & blower: The train contains the following items: Blower driven by a variable frequency drive, blower speed sensor, blower discharge pressure transmitter, combustion air pressure switch. There is no air damper or orifice plate in the air line. Gas inlet isolation valves, pressure regulator, Hi and Lo pressure switches, two automatic reset valves, orifice plate differential pressure, flow measurement system, flow control valve with integral actuator.

Safety & controls: The control system will utilize an Allen Bradley CompactLogix PLC (or any other brand like Siemens, Schneider, etc.). This PLC has an Ethernet/IP communications module. The system will also include an EZAutomation HMI display. This is a six inch color touchscreen panel. It will communicate with the PLC via Ethernet/IP.

Operator HMI: A 6 inch touch panel is supplied for the operator interface. The HMI is configured in a simple and straightforward manner to provide operators with useful information without overwhelming them. Alarms and warnings are only displayed when active.

Hydraulics: Hydraulic systems are sized according to the configuration and weight of the preheater structure. Water glycol fluid is standard. The cylinder will be sized to lift the lid with either 12” of compressed ceramic or 4” of cast refractory material

- Units can function as dryers and preheaters

- Lids are made of expanded metal with 12” compressed ceramic fiber lining

- Both oxy- and air-fuel designs are available

- PLC controls allow multiple burner profiles

- Individual flow controls for fuel and air save money

- Variable firing rates give better control over gas usage

- Self-diagnostic system with alarms

- Robust design starts first time everywhere

Preheaters & Dryers

- General information

- Variations

- Preheater system specifications

- Our technology – your advantage

You have modified your processes and purchased more efficient furnace equipment. You have added automation and have cut consumable expenses. You’ve saved all you can, right? Maybe not! Are you still using ancient preheater technology, running all day at one speed, doors wide open? Have you ever thought about how much that costs you?

INTECO PTI has a full line of dryers, preheaters, and combustion skids to fit your layout and your budget. We offer both oxy-fuel and air-fuel systems, so you don’t have to modify your plant floor or switch consumables. And, if you have not already chosen your consumables, let INTECO PTI design a system that will minimize your expenses.

INTECO PTI’s dryers, preheaters and combustion skids contain reliable starting mechanisms which wil start every time. The PLC controls allow variable firing rates and individual control of gas and oxygen profiles. This control results in less energy usage and increases savings.

Each INTECO PTI preheater comes with a visible alarm beacon and a self-diagnostic system, allowing your maintenance staff to quickly identify and correct any problems that may arise.

Further cost savings are available by utilizing your existing preheater and purchasing INTECO PTI’s control skid. This gives you all of the technology benefits of a full preheater system at a fraction of the cost. Let INTECO PTI tune your energy monster for good!

Vertical Ladle Preheaters

- All preheater systems are sized to fit the ladle or tundish

- Standard air/fuel or oxy/fuel burners are rated from 5 MMBTU to 15 MMBTU

- Bigger and smaller burners are available

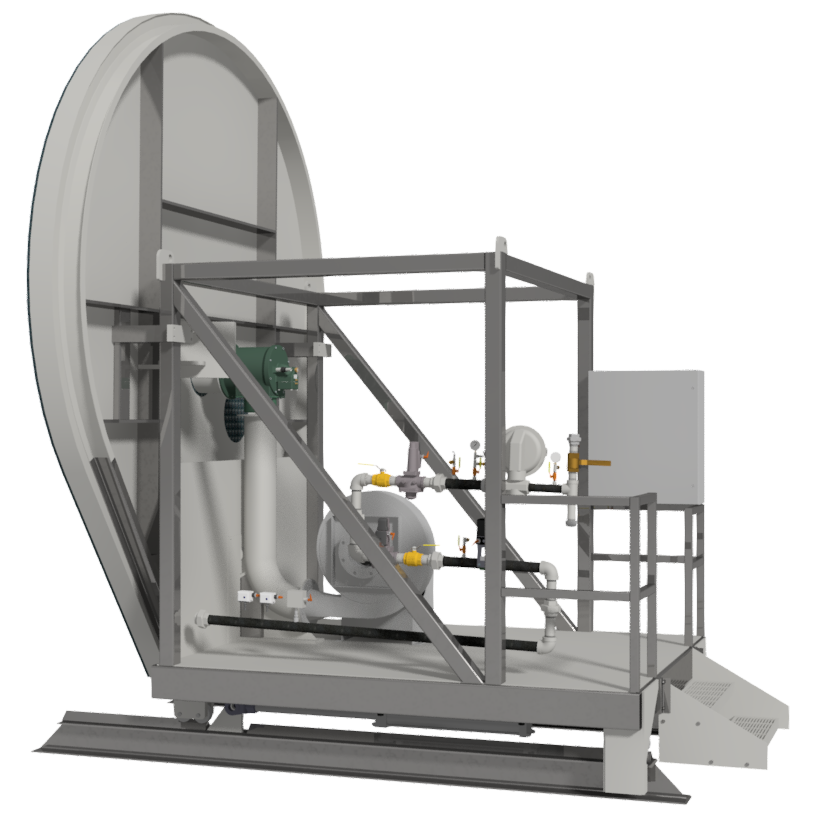

Enclosed Ladle Preheaters

- All air around ladle is captured and used for combustion An oxygen burner is used to combust all gases exiting the ladle exhaust

- All air around ladle is captured and used for combustion

- All air around ladle is captured and exhausted

Portable Dryers and Preheaters

- Each portable preheater is sized to fit the ladle

- The lift mechanism is sized to fit the crane hook with a single center lift

- The blower is located on the lid, the control train is located remotely

Tundish Preheaters

- Tundish preheaters typically have one burner per pour nozzle

- Tundish preheaters can be lift-on or tilt-design

Horizontal Ladle Preheaters

- The cart is powered with pneumatics or hydraulics

- The ladle lid, control train and power system are all located on the cart

Refractory lids: The standard refractory lid consists of an angle iron and expanded metal frame with compressed refractory blocks. Four stainless steel plates are embedded vertically in the compressed refractory to act as a stop and keep the refractory from being crushed if the lid is closed against the ladle edge.

Burners: Standard Air/Fuel or Oxy/Fuel burners are rated from 0.1 MMBTU to 15 MMBTU. The burners are direct spark ignited; they do not require pilot burners. The burner is supplied with a UV-flame scanner, spark plug, and ignition transformer.

Air/gas train & blower: The train contains the following items: Blower driven by a variable frequency drive, blower speed sensor, blower discharge pressure transmitter, combustion air pressure switch. There is no air damper or orifice plate in the air line. Gas inlet isolation valves, pressure regulator, Hi and Lo pressure switches, two automatic reset valves, orifice plate differential pressure, flow measurement system, flow control valve with integral actuator.

Safety & controls: The control system will utilize an Allen Bradley CompactLogix PLC (or any other brand like Siemens, Schneider, etc.). This PLC has an Ethernet/IP communications module. The system will also include an EZAutomation HMI display. This is a six inch color touchscreen panel. It will communicate with the PLC via Ethernet/IP.

Operator HMI: A 6 inch touch panel is supplied for the operator interface. The HMI is configured in a simple and straightforward manner to provide operators with useful information without overwhelming them. Alarms and warnings are only displayed when active.

Hydraulics: Hydraulic systems are sized according to the configuration and weight of the preheater structure. Water glycol fluid is standard. The cylinder will be sized to lift the lid with either 12” of compressed ceramic or 4” of cast refractory material

- Units can function as dryers and preheaters

- Lids are made of expanded metal with 12” compressed ceramic fiber lining

- Both oxy- and air-fuel designs are available

- PLC controls allow multiple burner profiles

- Individual flow controls for fuel and air save money

- Variable firing rates give better control over gas usage

- Self-diagnostic system with alarms

- Robust design starts first time everywhere