Temperature Measurement & Metallurgical Sampling

- General information

- Our technology – your advantege

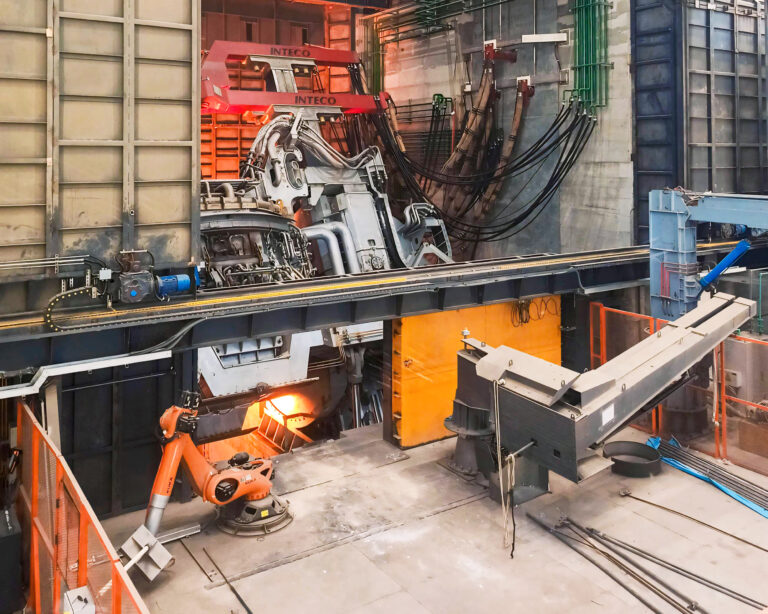

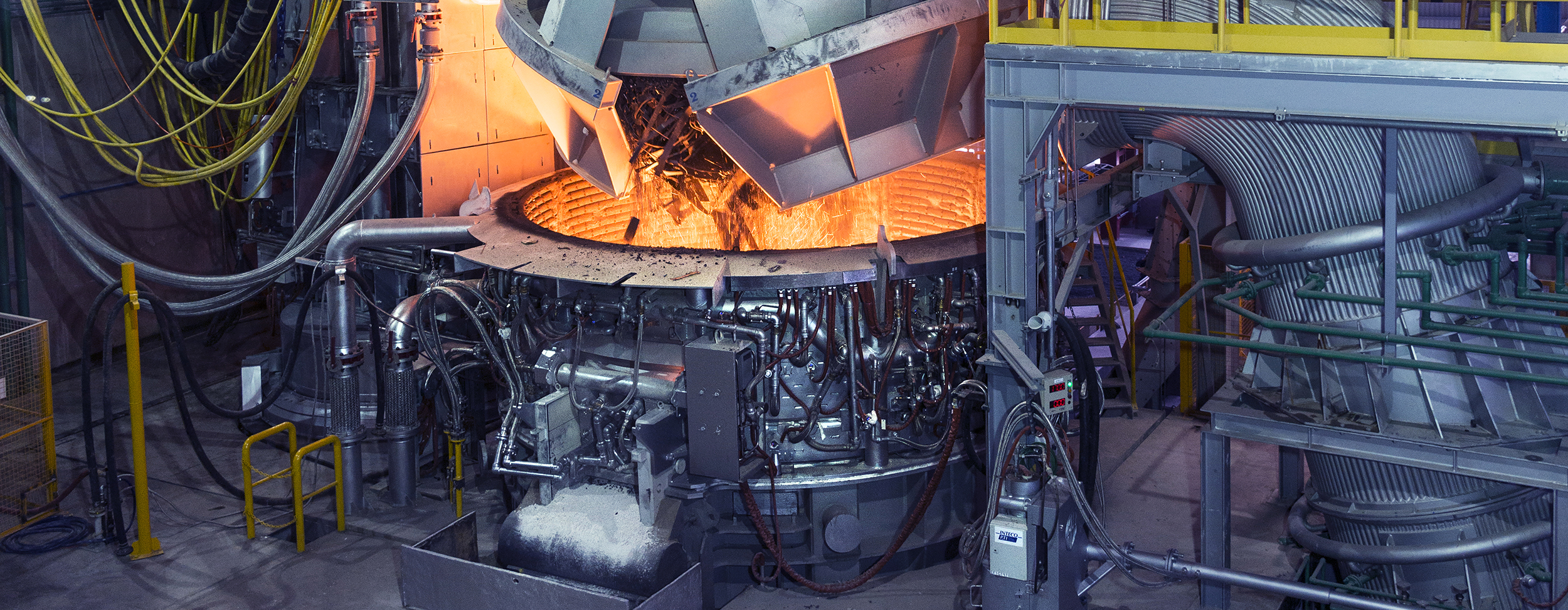

Based on its innovative JetBOx™ technology, INTECO PTI has developed a TempBox™ device to address safety concerns associated with temperature measurements and metallurgical sampling in steel production. Traditionally, measuring steel parameters through the slag door involves cleaning the area and opening the slag door, which allows cold air to infiltrate the Electric Arc Furnace (EAF). This not only increases energy usage but also poses safety risks from potential wild slag reactions and heat exposure. INTECO PTI solved the potential safety problems associated with conventional temperature and metallurgical sampling by using a JetBOx™ type of device through the EAF sidewall. This approach protects operators from heat and metal splashing while keeping the EAF door closed, considerably saving energy.

- Enhanced Operator Safety: Protects personnel from heat and metal splashing.

- Energy Efficiency: Closed slag door operation holds more slag in the EAF longer, reducing energy consumption.

- Yield Improvement: Minimizes yield loss by maintaining optimal conditions.

- Timely Sampling: Enables earlier temperature and metallurgical sampling in the process.

- Improved Sample Quality: Ensures higher quality and more reliable samples.

- Sampling options: supports both semi-automated and fully automated sampling through the EAF sidewall, providing a safer and more efficient environment for steelmaking personnel