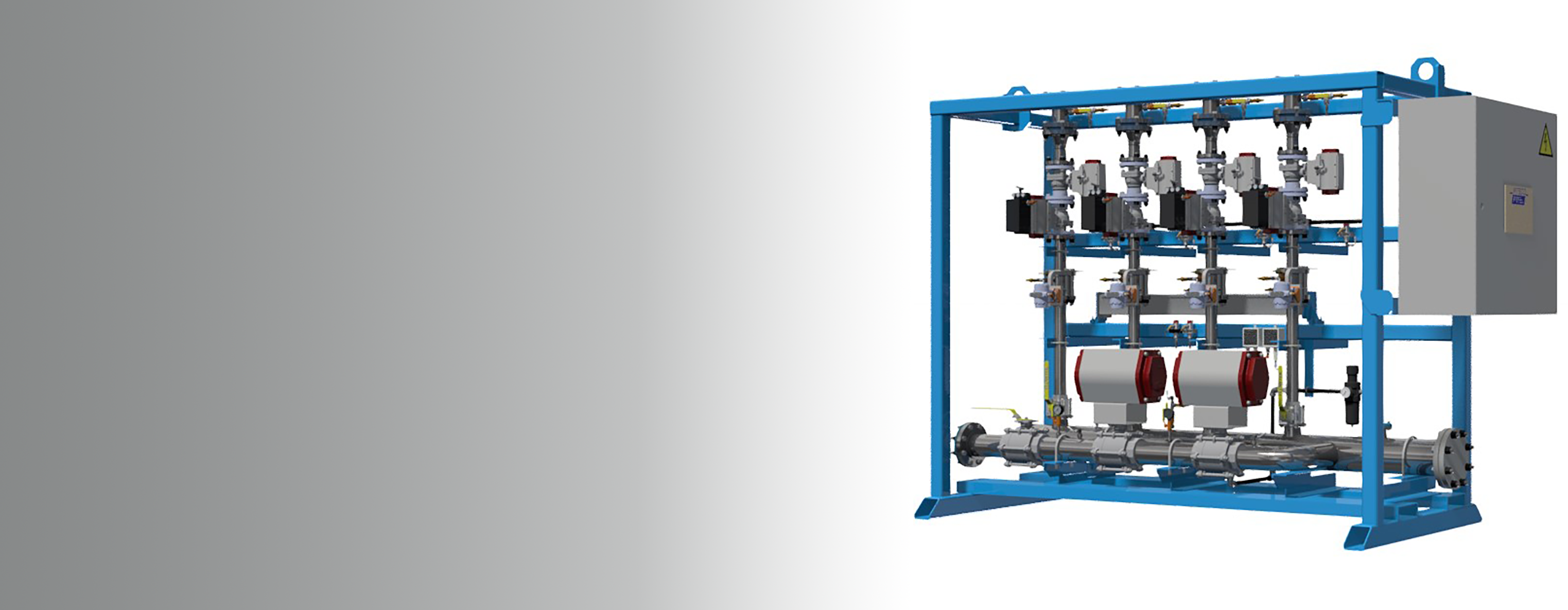

Valve trains

- General information

- Our technology- your advantage

PTI’s unique injector and train design not only saves capital cost during project installation, but also decreases operational cost for the life of the equipment, including on the valve train.

Most supersonic oxygen injectors require two oxygen and one fuel line to be attached to each injector. PTI’s supersonic injector requires only one oxygen and one fuel line. This reduces INTECO PTI’s control trains to only two control lines per injector. With one less oxygen line attached to each injector there is one less control for each injector on the control train, one less line on which to perform maintenance and one less set of spare parts to inventory.

INTECO PTI’s control trains have individual control zones for oxygen and fuel with spare capacity for future installation of additional injectors. All piping is made from stainless steel.

The instrumentation and valves normally do not require any maintenance during operation after the initial startup. However, should maintenance or troubleshooting ever be required, INTECO PTI’s flow control train is designed for easy access to guarantee fast system service. All valve trains are built fully, tested and calibrated at INTECO PTI’s facility.

- Individual Control Zones: Separate control zones for oxygen and fuel, with additional capacity for future injector installations

- Durable Construction: All piping is made from high-quality stainless steel

- Post-initial startup, the instrumentation and valves typically require no maintenance

- Flow control trains design ensures easy access for quick and efficient service

- Each valve train is fully built, tested, and calibrated at INTECO PTI’s facility, ensuring top-notch performance and reliability