Carbon Injection System

- General information

- Our technology – your advantage

Automated maintenance

The carbon injection system is self diagnostic and self adjusting. Features within the vessel help minimize carbon port plugging and ensure an even and consistent carbon flow. The carbon injection system has a self-diagnostic system that monitors the carbon flow along with critical system parameters. A robust design with high quality components, the carbon injection system will make carbon injection to any EAF virtually headache free.

Process optimization

INTECO PTI’s carbon injection system is designed to balance carbon distribution while minimizing carbon consumption. By injecting carbon to multiple points within the EAF, it provides a more consistent, foamy slag and a more homogenous steel bath. Since the carbon injection system is fully automatic, it frees up valuable operator time to concentrate on steelmaking.

Injection system upgrades

INTECO PTI has made a lot of upgrades to our injection technologies over the years. If you have an older system that is in need of upgrading, we can easily refurbish it with our newest technology package to make it in line with our current equipment in the steel Industry.

Automation

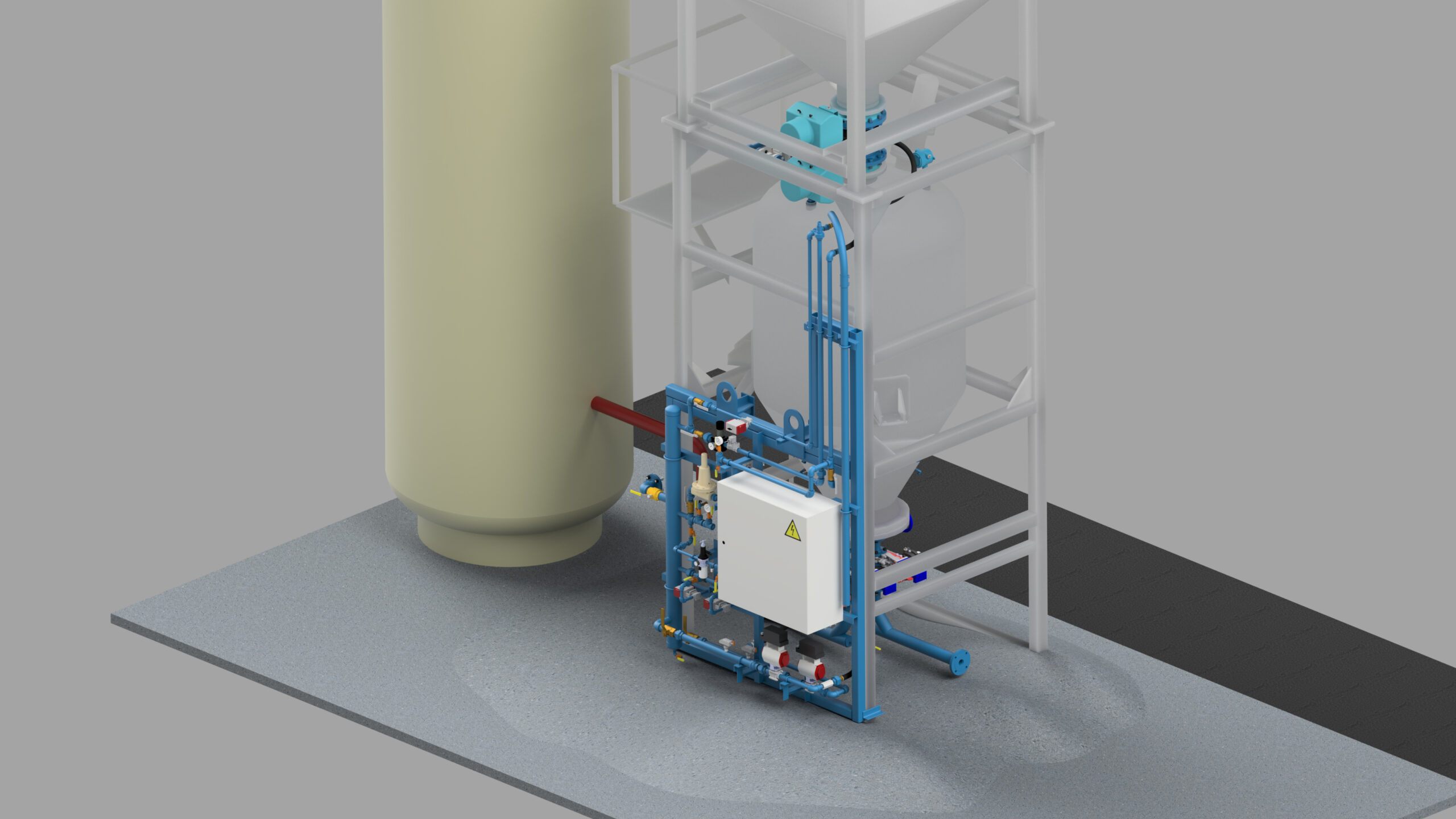

INTECO PTI’s carbon system is PLC controlled. To fit your needs, the PLC may be mounted directly on the vessel structure, or located remotely. INTECO PTI can customize its vessel automation systems to integrate with your current systems in order to reduce redundant control interfaces.

Closed loop flow control

A closed loop control of the vessel pressure and transport air flow regulates the carbon flow rate. The opening and closing of a cycling, carbon feed valve does not interrupt the carbon flow. With virtually no moving parts during the injection process, the carbon system lasts longer and requires less maintenance. Additionally, less floor space, fewer vessels and reduced maintenance make the INTECO PTI carbon injection system a “no brainer“ for any melt shop!

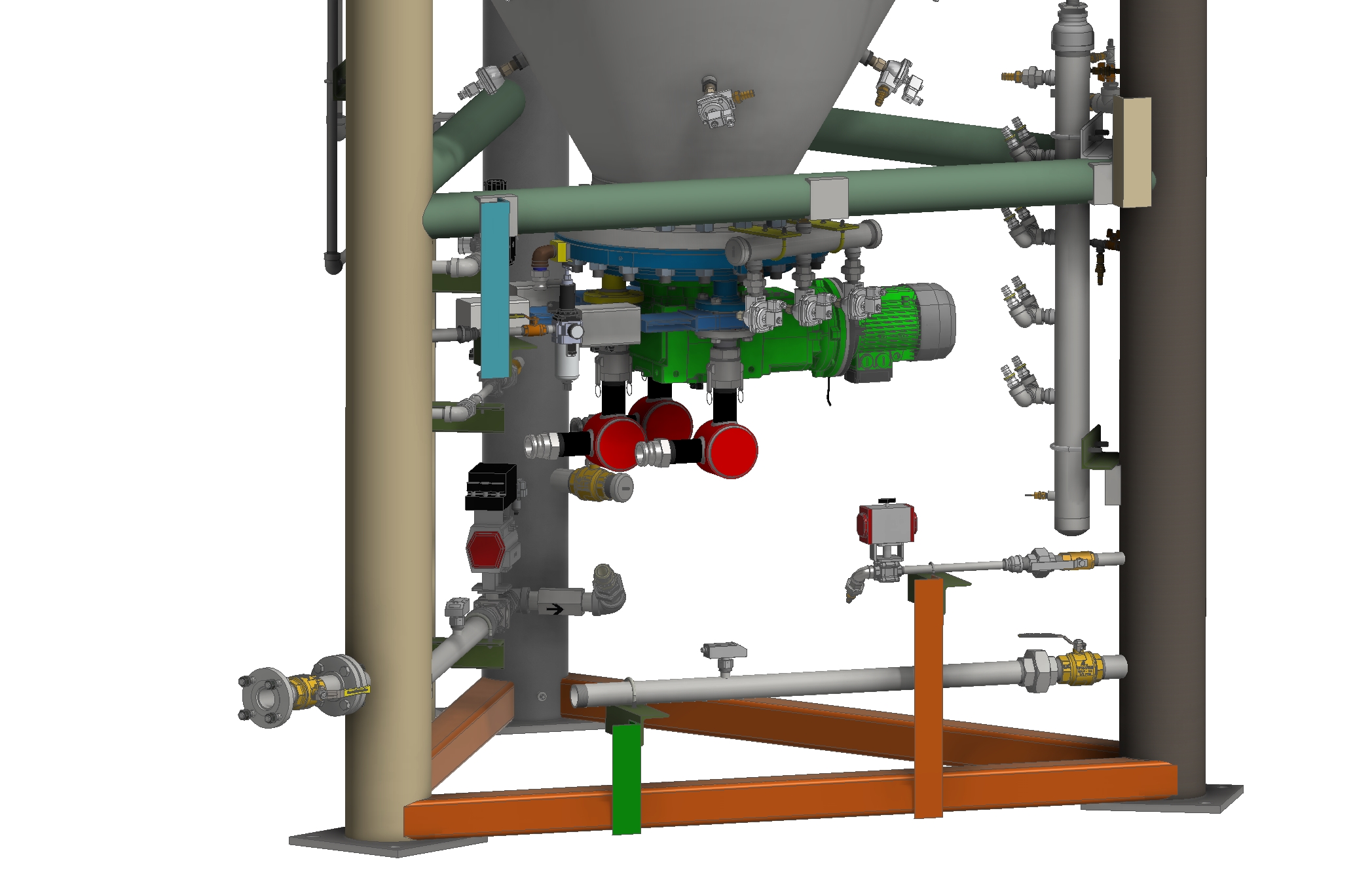

Multiple injection points via INTECO PTI‘s new rotary feed technology

The carbon injection system can be customized for up to 3 injection points, all from a single vessel. With fewer vessels required, it saves floor space and money! Single and dual outlets are also available in traditional pneumatic conveying method with knife gates if there is no need for a rotary.

- INTECO PTI‘s new rotary feed technology with three outlets

- Closed loop control flow and controlled carbon flow rates injected during melting

- Multiple injection points are available from a single source vessel

- System is self adjusting and self diagnostic

- Delivers uniterrupted flow of carbon to the EAF

- New anti-clogging software

- Injector integrates with existing operation system

Carbon Injection System

- General information

- Our technology – your advantage

Automated maintenance

The carbon injection system is self diagnostic and self adjusting. Features within the vessel help minimize carbon port plugging and ensure an even and consistent carbon flow. The carbon injection system has a self-diagnostic system that monitors the carbon flow along with critical system parameters. A robust design with high quality components, the carbon injection system will make carbon injection to any EAF virtually headache free.

Process optimization

INTECO PTI’s carbon injection system is designed to balance carbon distribution while minimizing carbon consumption. By injecting carbon to multiple points within the EAF, it provides a more consistent, foamy slag and a more homogenous steel bath. Since the carbon injection system is fully automatic, it frees up valuable operator time to concentrate on steelmaking.

Injection system upgrades

INTECO PTI has made a lot of upgrades to our injection technologies over the years. If you have an older system that is in need of upgrading, we can easily refurbish it with our newest technology package to make it in line with our current equipment in the steel Industry.

Automation

INTECO PTI’s carbon system is PLC controlled. To fit your needs, the PLC may be mounted directly on the vessel structure, or located remotely. INTECO PTI can customize its vessel automation systems to integrate with your current systems in order to reduce redundant control interfaces.

Closed loop flow control

A closed loop control of the vessel pressure and transport air flow regulates the carbon flow rate. The opening and closing of a cycling, carbon feed valve does not interrupt the carbon flow. With virtually no moving parts during the injection process, the carbon system lasts longer and requires less maintenance. Additionally, less floor space, fewer vessels and reduced maintenance make the INTECO PTI carbon injection system a “no brainer“ for any melt shop!

Multiple injection points via INTECO PTI‘s new rotary feed technology

The carbon injection system can be customized for up to 3 injection points, all from a single vessel. With fewer vessels required, it saves floor space and money! Single and dual outlets are also available in traditional pneumatic conveying method with knife gates if there is no need for a rotary.

- INTECO PTI‘s new rotary feed technology with three outlets

- Closed loop control flow and controlled carbon flow rates injected during melting

- Multiple injection points are available from a single source vessel

- System is self adjusting and self diagnostic

- Delivers uniterrupted flow of carbon to the EAF

- New anti-clogging software

- Injector integrates with existing operation system